Cosmopack Asia Awards 2024

Discover the winners of the 2024 editions of Cosmopack India Awards

Innovative Technology

VBrass™ Butter a.k.a (also known as) VEGAROL® MS Butter

VVF India Ltd (India)

IN: @vvfgroup; https://www.ulprospector.com/en/asia/PersonalCare/Detail/120205/8310778/Vegarol-MS-Butter

This ingredient is an emollient butter derived from mustard oil, obtained from mustard seeds. This is enhanced with select fractions of plant-based fatty alcohols, which transform the mustard oil into a soft fatty acid ester composition. The mustard oil is extracted from mustard seeds either via a mechanical screw press or by extraction with an organic solvent. It is then hydrolyzed using water to generate the mustard fatty acids, which are then distilled. After this, the mustard fatty acid residue is transformed into the VBrass™ Butter ingredient, when it reacts with the fatty alcohol. While it is synthetic, this ingredient is billed as offering similar benefits to shea butter, but at a third of the cost. Alongside this, the cultivation of the mustard is sustainable. For the skin, the ingredient brings moisturizing and barrier-strengthening properties, and the ingredient can be incorporated into skin, hair, and body formulas.

The jury appreciated how this ingredient takes mustard oil - traditionally used in India to massage skin and hair — and converts it into a butter to be used in cosmetic formulas.

The ingredient is an emollient butter derived from mustard oil that’s been obtained from mustard seeds. It has been enhanced with select fractions of plant-based fatty alcohols to transform the oil into a soft fatty acid ester composition. Extracted from mustard seeds via either a mechanical screw press or with an organic solvent, the mustard oil is then hydrolyzed using water to generate the mustard fatty acids, which are then distilled. After this, the mustard fatty acid residue is transformed into the VBrass™ Butter ingredient, when it reacts with the fatty alcohol. Billed as a more aGordable alternative to shea butter for formulators, the panel liked that the VBrass Butter’s carbon footprint is reduced, compared to that of shea butter. Another juror added that “the fact that the ingredient can be incorporated into skin, hair, and body formulas really makes the product very versatile.”

Make Up, Skin Care, Hair Formula

Don’t Be Shy Cheek Potion

Regi Cosmetics PVT. LTD. (India)

This blush fuses make-up and skin care benefits and is intended to tap into the well-aging trend and appeal to Gen Z consumers alike. The liquid cheek color is composed with an advanced hydra-gel matrix, which offers moisture-locking properties alongside a fresh, light sensation. And the brand’s Hyalu-Cushion technology, at 2%, is inspired by the effect of cosmetic procedures to instantly plump and fill wrinkles. Alongside this are soft-focus fillers to impart luminosity and blur imperfections; a Hold-Tech system that combines silicone resin with auto-fixing agents for long-wear comfort; and Madagascar ginger root extract at 0.2%, for protection against visible light, blue light, UV damage, and pollution. In terms of color, the formula is created with flexible pigments that offer blendability and buildable coverage, without appearing patchy or artificial.

Jurors praised this blush for combining “skin care with make-up,” for a product that not only appeals to Gen Z but is “marketable to a wider age range,” the panel pointed out. The liquid cheek color is formulated with an advanced hydra-gel matrix, which oGers moisture-locking properties alongside a fresh, light sensation. And the brand’s Hyalu- Cushion technology, at 2%, is inspired by the eGect of cosmetic procedures to plump and fill wrinkles. Alongside this are soft-focus fillers to impart luminosity and blur imperfections; a Hold-Tech system that combines silicone resin with auto-fixing agents for long-wear comfort; and Madagascar ginger root extract at 0.2%, for protection against visible light, blue light, UV damage, and pollution. One juror called the Don’t Be Shy Cheek Potion an “interesting, trendy, and caring cheek and blush product,” while another dubbed it “unique.” In addition, the formula’s flexible pigments oGer blendable and buildable coverage, without appearing patchy or artificial.

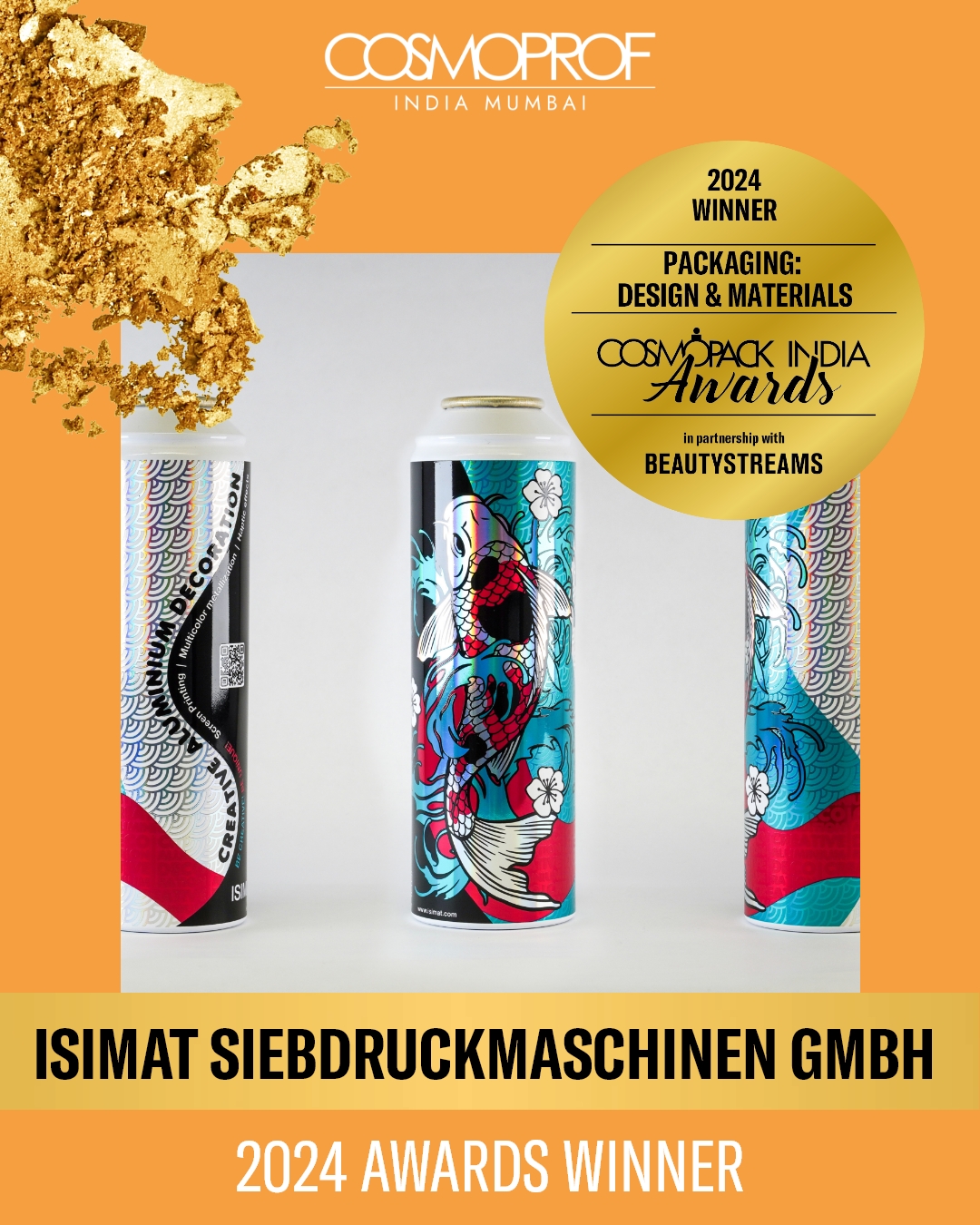

Packaging: Design & Materials

The Koi Can

ISIMAT Siebdruckmaschinen GmbH (Germany)

www.isimat.com/en/applications/aluminium-decoration/

This form of foiling decoration has been conceived to provide an aesthetically appealing packaging solution that offers both visual and haptic effects. The design combines – in one machine – different printing technologies, captured in ISIMAT’s patented inLINE® FOILING method. inLINE® FOILING can be used to create decoration effects spanning silkscreen printing, matte details, or a multi-metallic effect. Meanwhile, the concept’s use of UV technology ensures faster drying times and reduces energy consumption during the production process. The Koi Can techniques can be applied to aerosol bottles or cans, or for beverage packaging, such as premium, limited edition, or seasonal offerings.

Showcasing a form of foiling decoration that creates aesthetically appealing packaging with both visual and haptic eGects, jurors liked that The Koi Can oGers “dynamic design solutions,” and represents “good design possibilities and eGiciency.”

The concept uses a sngle machine to achieve the diGerent printing eGects, captured in ISIMAT’s patented inLINE® FOILING method. inLINE® FOILING can be used to create decoration eGects spanning silkscreen printing, matte details, or a multi metallic eGect. In addition, the method’s UV technology oGers faster drying times and reduced energy consumption during the production process. Its techniques can be applied to aerosol bottles or cans, or for beverage packaging, such as premium, limited edition, or seasonal oGerings. One panel member noted how “salable” the innovation is, while another pointed to its “high level of innovation and shelf appeal.”

Timeline

10 December 2024

Platform Opening

12 February 2025

Entries closing

28 February 2025

Finalists Announcement

17 March 2025

Deadline for Receiving Products

21 March 2025

Awards Ceremony

Winners Announcement